Compressor Gasis Naturalis Reciprocans Pistonis Industrialis CNG

Compressor CO2 pressionis humilis et pressionis altae

Compressor GNCest instrumentum ad gas naturale (CNG) comprimendum adhibitum, quod proprietates magnae stabilitatis, lati pressionis ambitus, magnae efficientiae atque energiae conservandae habet.

Compressor GNCpraecipue ad gas naturale comprimendum ad pressionem necessariam ad conservationem et transportationem adhibetur.

Inter praecipuas huius generis compressoris proprietates sunt hae:

1. Magna stabilitas: Fidelitatem et salutem processus compressionis CNG curant.

2. Lata amplitudo pressionis: Ad varias applicationum necessitates accommodari potest, pressio 25MPa attingere potest.

3. Potentia motoris: A 18.5 kW ad 350 kW, accommodabilis ad usus variarum magnitudinum

4. Designatio energiae conservandae: Consumptionem energiae minue et efficientiam energiae auge per technologias energiae conservandae provectas.

Praeterea,Compressores GNCVariis generibus praesto sunt, inter quos fixi, mobiles et super patines positi, ut variis usus condicionibus et institutionis requisitis satisfaciant. Fundantur in factoribus ut methodus refrigerationis, numerus graduum compressionis, numerus cylindrorum, etc.

Compressores GNCin varia genera dividi possunt, ut puta aqua refrigerata, aere refrigerata, uno stadio, duobus stadio, multis stadio, etc., necnon configurationes unius cylindri, duorum cylindri, multi cylindri. Hae classificationes optiones flexibiles praebent ad condiciones applicationis specificas implendas.

In GNCstationes benzinariaeCompressores GNCUna cum aliis instrumentis clavis, ut systematibus repositionis gasis altae pressionis, systematibus mensurae et moderationis gasis, systematibus purificationis gasis, et systematibus tutelae salutis, operantur ut operationem tutam et efficientem stationum impletionis CNG curent. Selectio et configuratio horum instrumentorum et systematum designum optimum requirit, fundatum in factoribus ut magnitudine, requisitis usus, et requisitis salutis stationis impletionis.

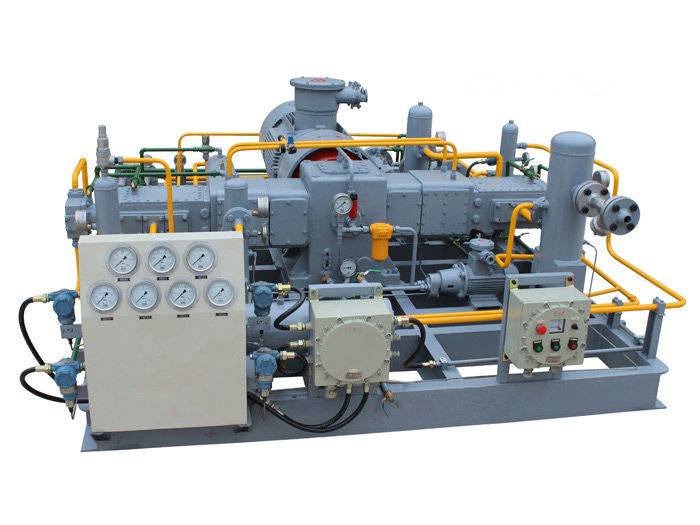

Unitas constat ex compressore principali, motore electrico, copula, volante, systemate fistularum, systemate refrigerationis, apparatu electrico, et apparatu auxiliari.

TheCompressor GNCSeries a societate nostra productae commodis praebent operationis stabilis, magni voluminis exhaustorum, temperaturae exhaustorum humilis, latae applicationis ambitu, humilis defectus ratis, usus tutus et fidus, et humilis sumptus sustentationis, et aptae sunt ad usum in stationibus CNG normae.

Certificata

TABULA PARAMETRORUM COMPRESSORIS HYDROGEI

| Numerus | Modellum | Fluxus (Nm3/h) | Pressio ingressus (Mpa) | Pressio exhausta (Mpa) | Medium | Potentia motoris (kW) | Dimensiones totales (mm) |

| 1 | ZW-0.5/15 | 24 | Pressio normalis | 1.5 | Hydrogenium | 7.5 | 1600*1300*1250 |

| 2 | ZW-0.16/30-50 | 240 | 3 | 5 | Hydrogenium | 11 | 1850*1300*1200 |

| 3 | ZW-0.45/22-26 | 480 | 2.2 | 2.6 | Hydrogenium | 11 | 1850*1300*1200 |

| 4 | ZW-0.36 /10-26 | ducenti | 1 | 2.6 | Hydrogenium | 18.5 | 2000*1350*1300 |

| 5 | ZW-1.2/30 | 60 | Pressio normalis | 3 | Hydrogenium | 18.5 | 2000*1350*1300 |

| 6 | ZW-1.0/1.0-15 | centum | 0.1 | 1.5 | Hydrogenium | 18.5 | 2000*1350*1300 |

| 7 | ZW-0.28/8-50 | CXX | 0.8 | 5 | Hydrogenium | 18.5 | 2100*1350*1150 |

| 8 | ZW-0.3/10-40 | CL | 1 | 4 | Hydrogenium | 22 | 1900*1200*1420 |

| 9 | ZW-0.65/8-22 | trecenti | 0.8 | 2.2 | Hydrogenium | 22 | 1900*1200*1420 |

| 10 | ZW-0.65/8-25 | trecenti | 0.8 | 25 | Hydrogenium | 22 | 1900*1200*1420 |

| 11 | ZW-0.4/(9-10)-35 | CLXXX | 0.9-1 | 3.5 | Hydrogenium | 22 | 1900*1200*1420 |

| 12 | ZW-0.8/(9-10)-25 | quadringenti | 0.9-1 | 2.5 | Hydrogenium | 30 | 1900*1200*1420 |

| 13 | DW-2.5/0.5-17 | ducenti | 0.05 | 1.7 | Hydrogenium | 30 | 2200*2100*1250 |

| 14 | ZW-0.4/(22-25)-60 | 350 | 2.2-2.5 | 6 | Hydrogenium | 30 | 2000*1600*1200 |

| 15 | DW-1.35/21-26 | 1500 | 2.1 | 2.6 | Hydrogenium | 30 | 2000*1600*1200 |

| 16 | ZW-0.5/(25-31)-43.5 | DCCXX | 2.5-3.1 | 4.35 | Hydrogenium | 30 | 2200*2100*1250 |

| 17 | DW-3.4/0.5-17 | 260 | 0.05 | 1.7 | Hydrogenium | 37 | 2200*2100*1250 |

| 18 | DW-1.0/7-25 | quadringenti | 0.7 | 2.5 | Hydrogenium | 37 | 2200*2100*1250 |

| 19 | DW-5.0/8-10 | 2280 | 0.8 | 1 | Hydrogenium | 37 | 2200*2100*1250 |

| 20 | DW-1.7/5-15 | 510 | 0.5 | 1.5 | Hydrogenium | 37 | 2200*2100*1250 |

| 21 | DW-5.0/-7 | 260 | Pressio normalis | 0.7 | Hydrogenium | 37 | 2200*2100*1250 |

| 22 | DW-3.8/1-7 | 360 | 0.1 | 0.7 | Hydrogenium | 37 | 2200*2100*1250 |

| 23 | DW-6.5/8 | 330 | Pressio normalis | 0.8 | Hydrogenium | 45 | 2500*2100*1400 |

| 24 | DW-5.0/8-10 | 2280 | 0.8 | 1 | Hydrogenium | 45 | 2500*2100*1400 |

| 25 | DW-8.4/6 | quingenti | Pressio normalis | 0.6 | Hydrogenium | 55 | 2500*2100*1400 |

| 26 | DW-0.7/(20-23)-60 | DCCCXL | 2-2.3 | 6 | Hydrogenium | 55 | 2500*2100*1400 |

| 27 | DW-1.8/47-57 | 4380 | 4.7 | 5.7 | Hydrogenium | 75 | 2500*2100*1400 |

| 28 | VW-5.8/0.7-15 | 510 | 0.07 | 1.5 | Hydrogenium | 75 | 2500*2100*1400 |

| 29 | DW-10/7 | 510 | Pressio normalis | 0.7 | Hydrogenium | 75 | 2500*2100*1400 |

| 30 | VW-4.9/2-20 | DCCCL | 0.2 | 2 | Hydrogenium | 90 | 2800*2100*1400 |

| 31 | DW-1.8/15-40 | 1500 | 1.5 | 4 | Hydrogenium | 90 | 2800*2100*1400 |

| 32 | DW-5/25-30 | 7000 | 2.5 | 3 | Hydrogenium | 90 | 2800*2100*1400 |

| 33 | DW-0.9/20-80 | mille | 2 | 8 | Hydrogenium | 90 | 2800*2100*1400 |

| 34 | DW-25/3.5-4.5 | 5700 | 0.35 | 0.45 | Hydrogenium | 90 | 2800*2100*1400 |

| 35 | DW-1.5/(8-12)-50 | DCCC | 0.8-1.2 | 5 | Hydrogenium | 90 | 2800*2100*1400 |

| 36 | DW-15/7 | DCCLXXX | Pressio normalis | 0.7 | Hydrogenium | 90 | 2800*2100*1400 |

| 37 | DW-5.5/2-20 | DCCCXL | 0.2 | 2 | Hydrogenium | 110 | 3400*2200*1300 |

| 38 | DW-11/0.5-13 | DCCCXL | 0.05 | 1.3 | Hydrogenium | 110 | 3400*2200*1300 |

| 39 | DW-14.5/0.04-20 | DCCLXXX | 0.004 | 2 | Hydrogenium | 132 | 4300*2900*1700 |

| 40 | DW-2.5/10-40 | 1400 | 1 | 4 | Hydrogenium | 132 | 4200*2900*1700 |

| 41 | DW-16/0.8-8 | 2460 | 0.08 | 0.8 | Hydrogenium | CLX | 4800*3100*1800 |

| 42 | DW-1.3/20-150 | 1400 | 2 | 15 | Hydrogenium | CLXXXV | 5000*3100*1800 |

| 43 | DW-16/2-20 | 1500 | 0.2 | 2 | Hydrogenium | 28 | 6500*3600*1800 |

PARAMETRI INQUISITIONIS SUBMITTE

Si vis nos tibi delineationem technicam accuratam et pretium praebere, quaesumus ut sequentes parametros technicos praebeas, et intra horas viginti quattuor ad inscriptionem electronicam vel telephonum tuum respondebimus.

1. Fluxus celeritas: ___Nm3/h

2. Pars gasis (mol%):

3. Pressio ingressus: __bar(g)

4. Temperatura ingressus: ___℃

5. Pressio emissionis: ___bar(g)

6. Temperatura exitus: ___℃

7. Locus institutionis: intus an foris?

8. Temperatura ambientis loci: ___℃

9. Fons potentiae: __V/__ Hz/__ Ph?

10. Modus refrigerandi gasis: refrigeratio aerea an aquatica? Estne aqua refrigerans 28-32℃ et 3-4 bar(g) in situ?

11. Classificatio electrica: periculosa an non periculosa?