Compressoris Diaphragmatis Augmentatoris Gasis Hydrogenii Typus GZ, Fabricator

Compressor diaphragmatis est compressor voluminis structurae specialis. Est methodus compressionis summi gradus in campo compressionis gasorum. Haec methodus compressionis pollutionem secundariam non habet. Praeclaram protectionem pro gas compresso praebet. Bona sigillatione praedita, gas compressum non polluitur oleo lubricante aliisque impuritatibus solidis. Ergo aptus est ad comprimendum gas altae puritatis, rari pretiosi, inflammabiles et explosivos, toxicos et noxios, corrosivos, et altae pressionis.

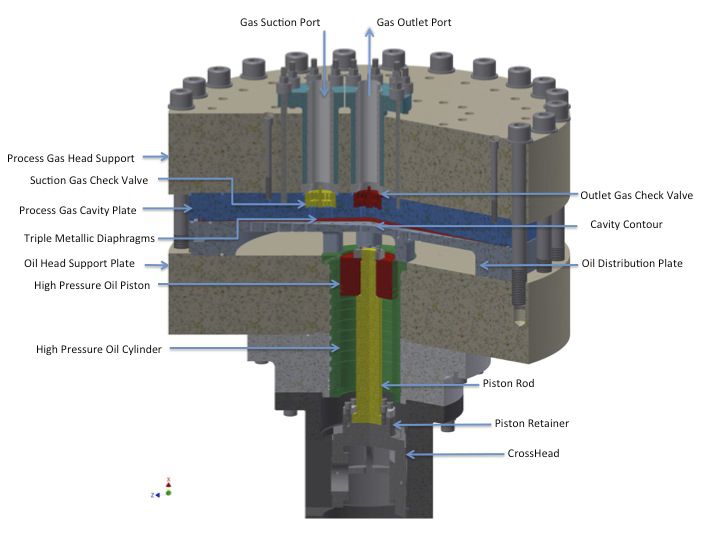

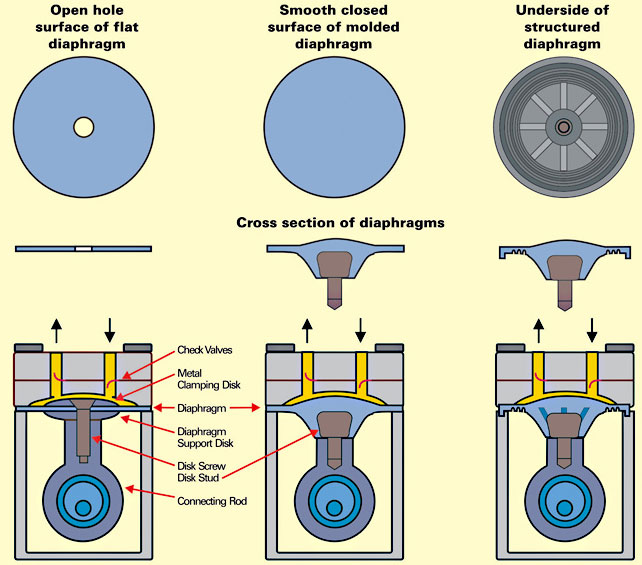

Compressor membranaceus est variatio compressoris classici reciprocantis cum subsidio et anulis pistonis et obturamento virgae. Compressio gasis fit per membranam flexibilem, non per elementum inductionis. Membrana reciprocans a virga et mechanismo arborei motorii impellitur. Sola membrana et arca compressoris cum gase pumpato in contactum veniunt. Ob hanc causam haec constructio aptissima est ad gases toxicos et explosivos pumpandos. Membrana satis certa esse debet ut onus gase pumpati sustineat. Proprietates chemicas idoneas et resistentiam temperaturae sufficientem habere debet.

Compressor diaphragmatis praecipue constat ex motoribus, basibus, capsulis arborei motorii, virgis arborei motorii, partibus cylindri, fistulis olei et gasi, systematibus moderationis electricae, et quibusdam accessionibus.

Compressor diaphragmatis est compressor positivus cum structura peculiari. Est methodus compressionis summi gradus in campo compressionis gasorum. Haec methodus compressionis nullam pollutionem secundariam habet et optimam protectionem pro gas compresso praebet. Magnam rationem compressionis habet, bonam vim obturandi praebet, et gas compressum non polluitur oleo lubricante aliisque impuritatibus solidis. Ergo aptus est ad comprimendum gases altae puritatis, raros et pretiosos, inflammabiles, explosivos, toxicos et noxios, corrosivos, et altae pressionis. Haec methodus compressionis plerumque internationaliter designatur ad comprimendum gases altae puritatis, gases inflammabiles et explosivos, gases toxicos, et oxygenium, et multa alia.

A. Secundum structuram classificata:

Compressorum diaphragmatis quattuor genera principalia sunt: Z, V, D, L, et cetera;

B. Secundum materiam diaphragmatis classificata:

Materiae diaphragmatum compressorum diaphragmatum sunt diaphragma metallicum (metalum nigrum et metallum non ferreum includens) et diaphragmata non metallica;

C. Secundum media compressa classificata:

Gasa rara et pretiosa, gasa inflammabilia et explosiva, gasa altae puritatis, gasa corrosiva, et cetera comprimere potest.

D. Classificata secundum societatem athleticam:

Virga connexa arboris motoriae, cursor arborei motoriae, etc.;

E. Secundum modum refrigerationis classificata:

Refrigeratio aquae, refrigeratio olei, refrigeratio aeris posterioris, refrigeratio naturalis, etc.;

F. Secundum modum lubricationis classificantur:

Lubricatio per pressionem, lubricatio per aspersionem, lubricatio externa coacta, etc.

Compressor tribus diaphragmatibus constat. Diaphragma circum aream firmiter premitur a latere olei hydraulici et latere gasis processus. Diaphragma a motore hydraulico in capite membranae impellitur ut compressionem et translationem gasis efficiat. Corpus principale compressoris diaphragmatis duobus systematibus constat: systemate olei hydraulici et systemate compressionis gasis, et membrana metallica haec duo systemata separat.

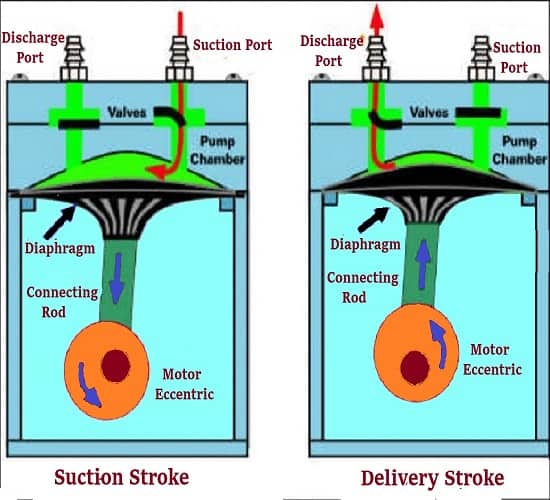

Structura compressoris diaphragmatis in duas partes dividitur: structuram hydraulicam et structuram vis pneumaticae. In processu compressionis, duo gradus sunt: cursus suctionis et cursus emissionis.

TABULA PARAMETRORUM COMPRESSORIS DIAPHRAGMATICI SERIE GZ

| Tabula parametrorum compressoris diaphragmatis seriei GZ | ||||||||

| Modellum | Refrigeratio aqua (L/h) | Fluxus (Nm³/h) | Ingressus pressio (MPa) | Prolatio pressio (MPa) | Dimensiones L × L × A (mm) | Pondus (kg) | Motor Potentia (kW) | |

| 1 | GZ-2/3 | mille | 2.0 | 0.0 | 0.3 | 1200×700×1100 | 0 | 2.2 |

| 2 | GZ-5/0.5-10 | ducenti | 5.0 | 0.05 | 1.0 | 1400×740×1240 | DCCL | 2.2 |

| 3 | GZ-5/13-200 | quadringenti | 5.0 | 1.3 | 20 | 1500×760×1200 | DCCCL | 4.0 |

| 4 | GZ-15/3-19 | quingenti | 15 | 0.3 | 1.9 | 1400×740×1330 | DCCCL | 4.0 |

| 5 | GZ-30/5-10 | quingenti | 30 | 0.5 | 1.0 | 1400×740×1330 | DCC | 3.0 |

| 6 | GZ-50/9.5-25 | DC | 50 | 0.95 | 2.5 | 1500×760×1200 | DCCCL | 5.5 |

| 7 | GZ-20/5-25 | DC | 20 | 0.5 | 2.5 | 1400×760×1600 | DCCL | 4.0 |

| 8 | GZ-20/5-30 | mille | 20 | 0.5 | 3.0 | 1400×760×1600 | DCCL | 5.5 |

| 9 | GZ-12/0.5-8 | quadringenti | 12 | 0.05 | 0.8 | 1500×760×1200 | DCCCL | 4.0 |

| 10 | GZ—5/0.5-8 | ducenti | 5.0 | 0.05 | 0.8 | 1400×740×1240 | DCCL | 2.2 |

| 11 | GZ-14/39-45 | quingenti | 14 | 3.9 | 4.5 | 1000×460×1100 | DCC | 2.2 |

| 12 | GZ-60/30-40 | 2100 | 60 | 3.0 | 4.0 | 1400×800×1300 | DCCCL | 3.0 |

| 13 | GZ-80/59-65 | quingenti | 80 | 5.9 | 6.5 | 1200×780×1200 | DCCCL | 7.5 |

| 14 | GZ-30/7-30 | mille | 30 | 0.7 | 3.0 | 1400×760×1600 | DCCL | 5.5 |

| 15 | GZ-10/0.5-10 | ducenti | 10 | 0.05 | 1.0 | 1400×800×1150 | quingenti | 4.0 |

| 16 | GZ-5/8 | ducenti | 5.0 | 0.0 | 0.8 | 1400×800×1150 | quingenti | 3.0 |

| 17 | GZ-15/10-100 | DC | 15 | 1.0 | 10 | 1400×850×1320 | mille | 5.5 |

| 18 | GZ-20/8-40 | mille | 20 | 0.8 | 4.0 | 1400×850×1320 | mille | 4.0 |

| 19 | GZ-20/32-160 | mille | 20 | 3.2 | 16 | 1400×850×1320 | mille | 5.5 |

| 20 | GZ-30/7.5-25 | mille | 30 | 0.75 | 2.5 | 1400×850×1320 | mille | 7.5 |

| 21 | GZ-5/0.1-7 | mille | 5.0 | 0.01 | 0.7 | 1200×750×1000 | DC | 2.2 |

| 22 | GZ-8/5 | mille | 8.0 | 0.0 | 0.5 | 1750×850×1250 | mille | 3.0 |

| 23 | GZ-11/0.36-6 | quadringenti | 11 | 0.036 | 0.6 | 1500×760×1200 | DCCCL | 3.0 |

| 24 | GZ-3/0.2 | mille | 3.0 | 0.0 | 0.02 | 1400×800×1300 | mille | 2.2 |

| 25 | GZ-80/20-35 | 1500 | 80 | 2.0 | 3.5 | 1500×800×1300 | 900 | 5.5 |

| 26 | GZ-15/30-200 | mille | 15 | 3.0 | 20 | 1400×1000×1200 | DCCC | 4.0 |

| 27 | GZ-12/4-35 | mille | 12 | 0.4 | 3.5 | 1500×1000×1500 | DCCC | 5.5 |

| 28 | GZ-10/0.5-7 | quadringenti | 10 | 0.05 | 0.7 | 1500×760×1200 | DCCCL | 3.0 |

| 29 | GZ-7/0.1-6 | mille | 7.0 | 0.01 | 0.6 | 1200×900×1200 | DCCC | 3.0 |

| 30 | GZ-20/4-20 | mille | 20 | 0.4 | 2.0 | 1400×850×1320 | DCCCL | 2.2 |

| 31 | GZF-42/120-350 | 1200 | 42 | 12 | 35 | 900×630×834 | 420 | 5.5 |

| 32 | GZ-7/0.1-6 | 1500 | 7 | 0.01 | 0.6 | 1200×900×1200 | DCCC | 3.0 |

| 33 | GZ-120/80-85 | 1500 | centum | 8.0 | 8.5 | 1200×900×1200 | DCCC | 4.0 |

| 34 | GZ-5/6-10 | mille | 5.0 | 0.6 | 1.0 | 1200×700×1100 | DCC | 2.2 |

| 35 | GZ-7/50-350 | mille | 7.0 | 5.0 | 35 | 1150×700×1100 | 450 | 3.0 |

| 36 | GZ-20/7-30 | mille | 20 | 0.7 | 3.0 | 1400×760×1100 | DCCCL | 4.0 |

| 37 | GZ-62/40-56 | 1500 | 62 | 4.0 | 5.6 | 1200×700×1100 | 450 | 3.0 |

| 38 | GZ-15/10-12 | 1500 | 15 | 1.0 | 1.2 | 1200×700×1100 | quingenti | 3.0 |

| 39 | GZ-14/6-20 | mille | 14 | 0.6 | 2.0 | 1200×700×1100 | quingenti | 2.2 |

| 40 | GZ-350/120-450 | mille | 350 | 5-20 | 450 | 2350×1850×1100 | 7000 | 37 |

| 41 | GZ-936/8-8.3 | MM | 936 | 0.8 | 0.83 | 2100×1500×1700 | MM | 15 |