Compressor Oxygenii Altae Puritatis Typi Gz Gasis Naturalis Hydrogenii Diaphragmatis Compressor Nitrogenii LPG

Compressor gasorum diaphragmatis est compressor voluminis structurae specialis. Est methodus compressionis summi gradus in campo compressionis gasorum. Haec methodus compressionis pollutionem secundariam non habet. Praeclaram protectionem pro gaso compresso praebet. Bona obturatione praeditus, gas compressum non polluitur oleo lubricante aliisque impuritatibus solidis. Ergo aptus est ad comprimendum gasum altae puritatis, rariorum pretiosorum, inflammabilium et explosivorum, toxicorum et noxiorum, corrosivorum, et altae pressionis.

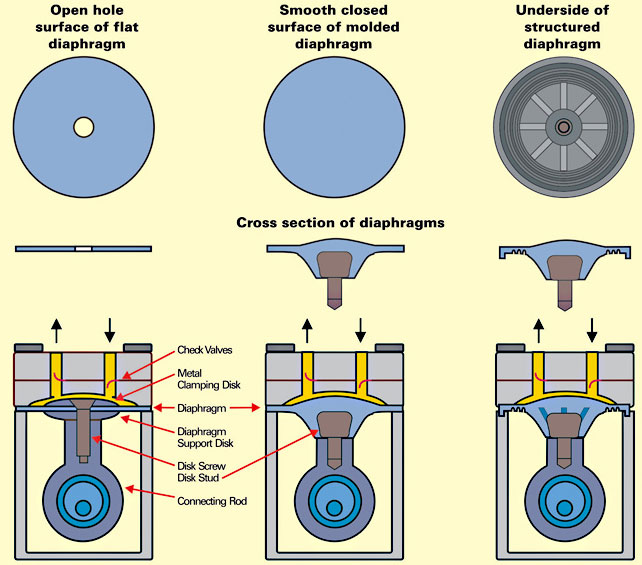

Compressor gasorum diaphragmatis est variatio compressoris classici reciprocantis cum subsidio et anulis pistonis et obturamento virgae. Compressio gasorum fit per membranam flexibilem, non per elementum inductionis. Membrana reciprocans a virga et mechanismo arborei motorii impellitur. Sola membrana et arca compressoris cum gaso pumpato in contactum veniunt. Ob hanc causam haec constructio aptissima est ad gasa toxica et explosiva pumpanda. Membrana satis certa esse debet ut onus gasi pumpati sustineat. Proprietates chemicas idoneas et resistentiam temperaturae sufficientem habere debet.

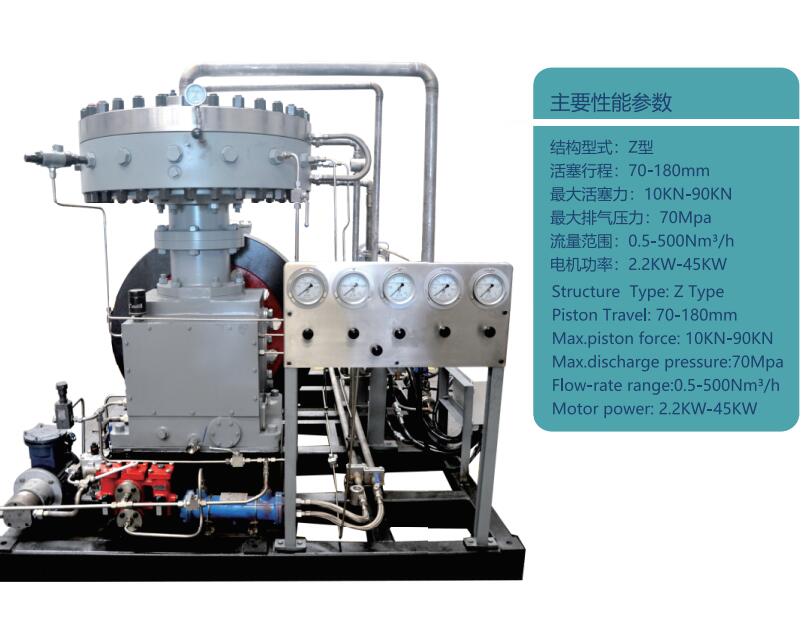

Compressor diaphragmatis praecipue constat ex motoribus, basibus, capsulis arborei motorii, virgis arborei motorii, partibus cylindri, canalibus olei et gasi, systematibus moderationis electricae, et quibusdam accessionibus.

Principium ProcessusCompressor gasis membranae

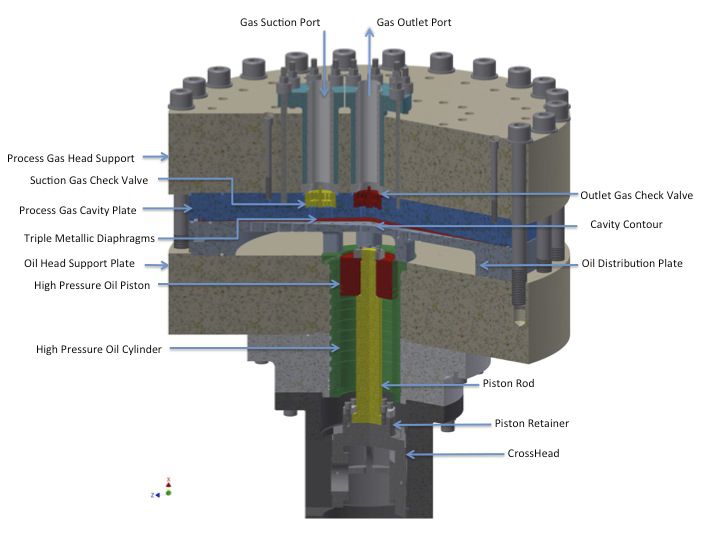

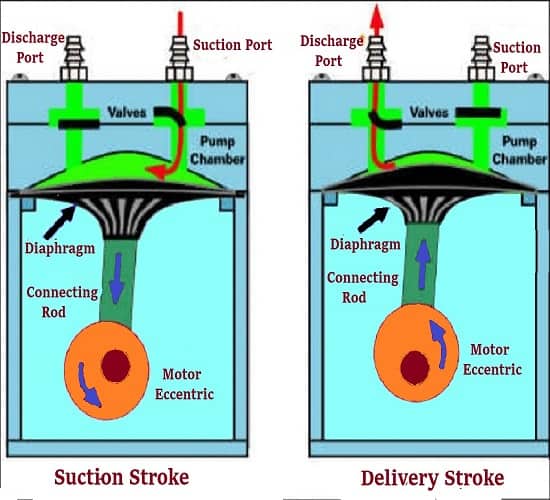

Compressor diaphragmatis tribus diaphragmatibus constat. Diaphragma, latere olei hydraulici et latere gasis processus, circa aream circumdantem premendus est. Diaphragma a motore hydraulico in capite membranae impellitur ut compressionem et translationem gasis efficiat. Corpus principale compressoris diaphragmatis duobus systematibus constat: systemate olei hydraulici et systemate compressionis gasis, membrana metallica haec duo systemata separat.

Structura compressoris diaphragmatis in duas partes dividitur: structuram hydraulicam et structuram vis pneumaticae. In processu compressionis, duo gradus sunt: cursus suctionis et cursus emissionis.

Commoda compressoris diaphragmatis:

- Bona obsignatio.

- Cylindrus bonam vim dissipationis caloris habet.

- Omnino sine oleo, puritas gasis maior quam 99.999% esse promitti potest.

- Altae rationes compressionis, alta pressio exitus usque ad 1000bar.

- Longa vita utilis, plus quam viginti annos.

Index Referentiarum Compressorum Diaphragmatum Seriei GZ

| Modellum | Consumptio aquae refrigerantis (t/h) | Dislocatio (Nm³/h) | Pressio inductionis (MPa) | Pressio exhausta (MPa) | Dimensiones L × L × A (mm) | Pondus (t) | Potentia Motoris (kW) |

| GZ-2/3 | 1.0 | 2.0 | 0.0 | 0.3 | 1200×700×1100 | 0.5 | 2.2 |

| GZ-5/0.5-10 | 0.2 | 5.0 | 0.05 | 1.0 | 1400×740×1240 | 0.65 | 2.2 |

| GZ-5/13-200 | 0.4 | 5.0 | 1.3 | 20 | 1500×760×1200 | 0.75 | 4.0 |

| GZ-15/3-19 | 0.5 | 15 | 0.3 | 1.9 | 1400×740×1330 | 0.75 | 4.0 |

| GZ-30/5-10 | 0.5 | 30 | 0.5 | 1.0 | 1400×740×1330 | 0.7 | 3.0 |

| GZ-50/9.5-25 | 0.6 | 50 | 0.95 | 2.5 | 1500×760×1200 | 0.75 | 5.5 |

| GZ-20/5-25 | 0.6 | 20 | 0.5 | 2.5 | 1400×760×1600 | 0.65 | 4.0 |

| GZ-20/5-30 | 1.0 | 20 | 0.5 | 3.0 | 1400×760×1600 | 0.65 | 5.5 |

| GZ-12/0.5-8 | 0.4 | 12 | 0.05 | 0.8 | 1500×760×1200 | 0.75 | 4.0 |

| GZ—5/0.5-8 | 0.2 | 5.0 | 0.05 | 0.8 | 1400×740×1240 | 0.65 | 2.2 |

| GZ-14/39-45 | 0.5 | 14 | 3.9 | 4.5 | 1000×460×1100 | 0.7 | 2.2 |

| GZ-60/30-40 | 2.1 | 60 | 3.0 | 4.0 | 1400×800×1300 | 0.75 | 3.0 |

| GZ-80/59-65 | 0.5 | 80 | 5.9 | 6.5 | 1200×780×1200 | 0.75 | 7.5 |

| GZ-30/7-30 | 1.0 | 30 | 0.7 | 3.0 | 1400×760×1600 | 0.65 | 5.5 |

| GZ-10/0.5-10 | 0.2 | 10 | 0.05 | 1.0 | 1400×800×1150 | 0.5 | 4.0 |

| GZ-5/8 | 0.2 | 5.0 | 0.0 | 0.8 | 1400×800×1150 | 0.5 | 3.0 |

| GZ-15/10-100 | 0.6 | 15 | 1.0 | 10 | 1400×850×1320 | 1.0 | 5.5 |

| GZ-20/8-40 | 1.0 | 20 | 0.8 | 4.0 | 1400×850×1320 | 1.0 | 4.0 |

| GZ-20/32-160 | 1.0 | 20 | 3.2 | 16 | 1400×850×1320 | 1.0 | 5.5 |

| GZ-30/7.5-25 | 1.0 | 30 | 0.75 | 2.5 | 1400×850×1320 | 1.0 | 7.5 |

| GZ-5/0.1-7 | 1.0 | 5.0 | 0.01 | 0.7 | 1200×750×1000 | 0.6 | 2.2 |

| GZ-8/5 | 1.0 | 8.0 | 0.0 | 0.5 | 1750×850×1250 | 1.0 | 3.0 |

| GZ-11/0.36-6 | 0.4 | 11 | 0.036 | 0.6 | 1500×760×1200 | 0.75 | 3.0 |

| GZ-3/0.2 | 1.0 | 3.0 | 0.0 | 0.02 | 1400×800×1300 | 1.0 | 2.2 |

| GZ-80/20-35 | 1.5 | 80 | 2.0 | 3.5 | 1500×800×1300 | 0.9 | 5.5 |

| GZ-15/30-200 | 1.0 | 15 | 3.0 | 20 | 1400×1000×1200 | 0.8 | 4.0 |

| GZ-12/4-35 | 1.0 | 12 | 0.4 | 3.5 | 1500×1000×1500 | 0.8 | 5.5 |

| GZ-10/0.5-7 | 0.4 | 10 | 0.05 | 0.7 | 1500×760×1200 | 0.75 | 3.0 |

| GZ-7/0.1-6 | 1.0 | 7.0 | 0.01 | 0.6 | 1200×900×1200 | 0.8 | 3.0 |

| GZ-20/4-20 | 1.0 | 20 | 0.4 | 2.0 | 1400×850×1320 | 0.75 | 2.2 |

Quomodo pretium obtineatur, cum compressor ad mensuram aptatus sit?

Nota: Pro alio compressore gasii ad usum aptato, quaeso informationes infra scriptas ad officinam nostram mitte ut sumptus productionis pro re tua computetur.

1. Fluxus celeritas: _______Nm3/h

2. Medium Gasosum: ______ Hydrogenium an Gas Naturale an Oxygenium an aliud gas?

3. Pressio ingressus: ___bar(g)

4. Temperatura ingressus: _____ºC

5. Pressio exitus: ____bar (g)

6. Temperatura exitus: ____ºC

7. Locus institutionis: _____intus an foris?

8. Temperatura ambientis loci: ____ºC

9. Fons potentiae: _V/ _Hz/ _3Ph?

10. Modus refrigerandi gasis: ______ refrigeratio aeris an refrigeratio aquae?