Compressor Auxilii Reciprocans Pistonis CO2

Compressor CO2 pressionis humilis et pressionis altae

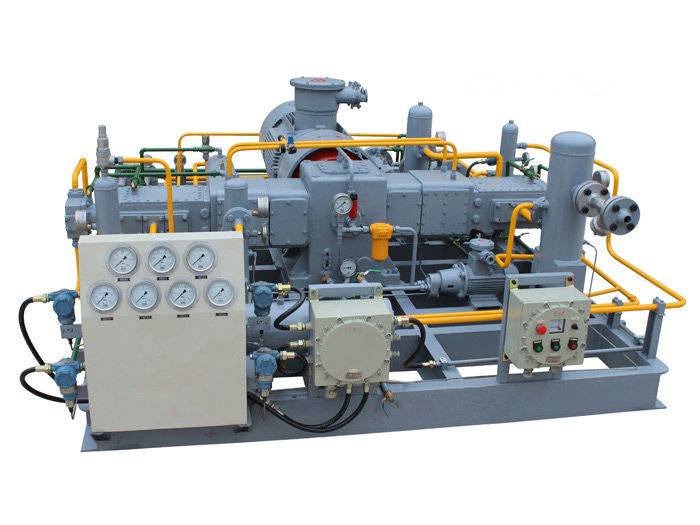

Compressor reciprocansCompressor motus reciprocus pistonis est, qui pressionem gasis efficit et gasis distributionem efficit. Constat praecipue ex camera operativa, partibus transmissionis, corpore, et partibus auxiliaribus. Camera operativa directe ad gas comprimendum adhibetur; piston a virga pistonis in cylindro ad motum reciprocum impellitur. Volumen camerae operativae in utroque latere pistonis vicissim mutatur. Volumen in uno latere gasis decrescit propter pressionem auctam per valvulam exhalantem, volumen autem in uno latere crescit propter pressionem aeris per valvulam ad gas absorbendum imminutam.

Varios compressores gasii habemus, ut compressorem hydrogenii, compressorem nitrogenii, compressorem gasii naturalis, compressorem biogasii, compressorem ammoniae, compressorem LPG, compressorem CNG, compressorem gasii mixti, et cetera.

Parametri producti

1. Verticalis typi Z: dislocatio ≤ 3m³/min, pressio 0.02MPa-4Mpa (secundum necessitates reales selecta)

2. Typus symmetricus D-typus: dislocatio ≤ 10m³/min, pressio 0.2MPa-2.4Mpa (secundum necessitates reales selecta)

3. Volumen exhaustorium formae V a 0.2m³/min ad 40m³/min variat. Pressio exhaustoria a 0.2MPa ad 25MPa variat (secundum necessitates reales selecta).

Proprietates Producti

1. Productum habet proprietates sonitus humilis, vibrationis humilis, structurae compactae, operationis lenis, salutis et firmitatis, et gradus automationis alti. Etiam configurari potest cum systemate remotae ostensionis et moderationis data impulso secundum necessitates emptoris.

2. Instructum functionibus alarmis et clausurae pro pressione olei humili, pressione aquae humili, temperatura alta, pressione ingressus humili, et pressione exhaustus alta compressoris, quo fit ut operatio compressoris certior fiat.

Introductio Structurae

Unitas constat ex compressore principali, motore electrico, copula, volante, systemate fistularum, systemate refrigerationis, apparatu electrico, et apparatu auxiliari.

Methodus lubricationis

1. Nullum oleum 2. Oleum praesto (secundum necessitates reales selectum)

Methodus refrigerationis

1. Refrigeratio aquae 2. Refrigeratio aeris 3. Refrigeratio mixta (secundum necessitates reales selecta)

Forma structurae generalis

Genus tecti fixi, mobilis, manubrio affixi, insono insono (secundum necessitates reales selecti)

Usus compressoris CO2

Dioxidum carbonis (CO2) est gas late adhibitum cum multis usibus et applicationibus. Hic sunt nonnullae applicationes communes dioxidi carbonis:

Industria cibaria et potuum:.Bullas et saporem potionum augere potest, et cibum in apotheca durare.

Industria medica: IdSaepe adhibetur ut anaestheticum, ad therapiam respiratoriam et ventilationem artificialem, necnon ad chirurgiam endoscopicam et congelationem textuum.

Exstinctio ignis: Idflammas efficaciter extinguere potest sine circuitibus brevibus in apparatibus electricis efficiendis.

Soldatura scuti gasii: IdStratum protectivum in area soldadurae formare potest ad oxygenium ingredi prohibendum et reactiones oxidationis minuendas.

Extractio fluidi supercritici:Haec methodus late in industriis sicut cibariis, medicinis, et cosmeticis adhibetur.

Recuperatio olei aucta:Iniectio dioxidi carbonis pressionem in puteo olei augere et fluxum olei ad puteum producentem impellere potest.

Spuma exstinguens: HocGenus spumae ignem liquidum inflammabilem efficaciter extinguere et stratum isolationis formare potest ad propagationem ignis prohibendam.

Hae sunt tantum nonnullae applicationes communes dioxidi carbonii, quae etiam usus importantes in aliis campis et processibus habent. Quamquam dioxidum carbonii multis modis utile est, etiam operam dare debemus ad moderandas et reducendas emissiones dioxidi carbonii ut mutationi climatis et provocationibus environmentalibus occurramus.

TABULA PARAMETRORUM COMPRESSORIS HYDROGEI

| Numerus | Modellum | Fluxus (Nm3/h) | Pressio ingressus (Mpa) | Pressio exhausta (Mpa) | Medium | Potentia motoris (kW) | Dimensiones totales (mm) |

| 1 | ZW-0.5/15 | 24 | Pressio normalis | 1.5 | Hydrogenium | 7.5 | 1600*1300*1250 |

| 2 | ZW-0.16/30-50 | 240 | 3 | 5 | Hydrogenium | 11 | 1850*1300*1200 |

| 3 | ZW-0.45/22-26 | 480 | 2.2 | 2.6 | Hydrogenium | 11 | 1850*1300*1200 |

| 4 | ZW-0.36 /10-26 | ducenti | 1 | 2.6 | Hydrogenium | 18.5 | 2000*1350*1300 |

| 5 | ZW-1.2/30 | 60 | Pressio normalis | 3 | Hydrogenium | 18.5 | 2000*1350*1300 |

| 6 | ZW-1.0/1.0-15 | centum | 0.1 | 1.5 | Hydrogenium | 18.5 | 2000*1350*1300 |

| 7 | ZW-0.28/8-50 | CXX | 0.8 | 5 | Hydrogenium | 18.5 | 2100*1350*1150 |

| 8 | ZW-0.3/10-40 | CL | 1 | 4 | Hydrogenium | 22 | 1900*1200*1420 |

| 9 | ZW-0.65/8-22 | trecenti | 0.8 | 2.2 | Hydrogenium | 22 | 1900*1200*1420 |

| 10 | ZW-0.65/8-25 | trecenti | 0.8 | 25 | Hydrogenium | 22 | 1900*1200*1420 |

| 11 | ZW-0.4/(9-10)-35 | CLXXX | 0.9-1 | 3.5 | Hydrogenium | 22 | 1900*1200*1420 |

| 12 | ZW-0.8/(9-10)-25 | quadringenti | 0.9-1 | 2.5 | Hydrogenium | 30 | 1900*1200*1420 |

| 13 | DW-2.5/0.5-17 | ducenti | 0.05 | 1.7 | Hydrogenium | 30 | 2200*2100*1250 |

| 14 | ZW-0.4/(22-25)-60 | 350 | 2.2-2.5 | 6 | Hydrogenium | 30 | 2000*1600*1200 |

| 15 | DW-1.35/21-26 | 1500 | 2.1 | 2.6 | Hydrogenium | 30 | 2000*1600*1200 |

| 16 | ZW-0.5/(25-31)-43.5 | DCCXX | 2.5-3.1 | 4.35 | Hydrogenium | 30 | 2200*2100*1250 |

| 17 | DW-3.4/0.5-17 | 260 | 0.05 | 1.7 | Hydrogenium | 37 | 2200*2100*1250 |

| 18 | DW-1.0/7-25 | quadringenti | 0.7 | 2.5 | Hydrogenium | 37 | 2200*2100*1250 |

| 19 | DW-5.0/8-10 | 2280 | 0.8 | 1 | Hydrogenium | 37 | 2200*2100*1250 |

| 20 | DW-1.7/5-15 | 510 | 0.5 | 1.5 | Hydrogenium | 37 | 2200*2100*1250 |

| 21 | DW-5.0/-7 | 260 | Pressio normalis | 0.7 | Hydrogenium | 37 | 2200*2100*1250 |

| 22 | DW-3.8/1-7 | 360 | 0.1 | 0.7 | Hydrogenium | 37 | 2200*2100*1250 |

| 23 | DW-6.5/8 | 330 | Pressio normalis | 0.8 | Hydrogenium | 45 | 2500*2100*1400 |

| 24 | DW-5.0/8-10 | 2280 | 0.8 | 1 | Hydrogenium | 45 | 2500*2100*1400 |

| 25 | DW-8.4/6 | quingenti | Pressio normalis | 0.6 | Hydrogenium | 55 | 2500*2100*1400 |

| 26 | DW-0.7/(20-23)-60 | DCCCXL | 2-2.3 | 6 | Hydrogenium | 55 | 2500*2100*1400 |

| 27 | DW-1.8/47-57 | 4380 | 4.7 | 5.7 | Hydrogenium | 75 | 2500*2100*1400 |

| 28 | VW-5.8/0.7-15 | 510 | 0.07 | 1.5 | Hydrogenium | 75 | 2500*2100*1400 |

| 29 | DW-10/7 | 510 | Pressio normalis | 0.7 | Hydrogenium | 75 | 2500*2100*1400 |

| 30 | VW-4.9/2-20 | DCCCL | 0.2 | 2 | Hydrogenium | 90 | 2800*2100*1400 |

| 31 | DW-1.8/15-40 | 1500 | 1.5 | 4 | Hydrogenium | 90 | 2800*2100*1400 |

| 32 | DW-5/25-30 | 7000 | 2.5 | 3 | Hydrogenium | 90 | 2800*2100*1400 |

| 33 | DW-0.9/20-80 | mille | 2 | 8 | Hydrogenium | 90 | 2800*2100*1400 |

| 34 | DW-25/3.5-4.5 | 5700 | 0.35 | 0.45 | Hydrogenium | 90 | 2800*2100*1400 |

| 35 | DW-1.5/(8-12)-50 | DCCC | 0.8-1.2 | 5 | Hydrogenium | 90 | 2800*2100*1400 |

| 36 | DW-15/7 | DCCLXXX | Pressio normalis | 0.7 | Hydrogenium | 90 | 2800*2100*1400 |

| 37 | DW-5.5/2-20 | DCCCXL | 0.2 | 2 | Hydrogenium | 110 | 3400*2200*1300 |

| 38 | DW-11/0.5-13 | DCCCXL | 0.05 | 1.3 | Hydrogenium | 110 | 3400*2200*1300 |

| 39 | DW-14.5/0.04-20 | DCCLXXX | 0.004 | 2 | Hydrogenium | 132 | 4300*2900*1700 |

| 40 | DW-2.5/10-40 | 1400 | 1 | 4 | Hydrogenium | 132 | 4200*2900*1700 |

| 41 | DW-16/0.8-8 | 2460 | 0.08 | 0.8 | Hydrogenium | CLX | 4800*3100*1800 |

| 42 | DW-1.3/20-150 | 1400 | 2 | 15 | Hydrogenium | CLXXXV | 5000*3100*1800 |

| 43 | DW-16/2-20 | 1500 | 0.2 | 2 | Hydrogenium | 28 | 6500*3600*1800 |